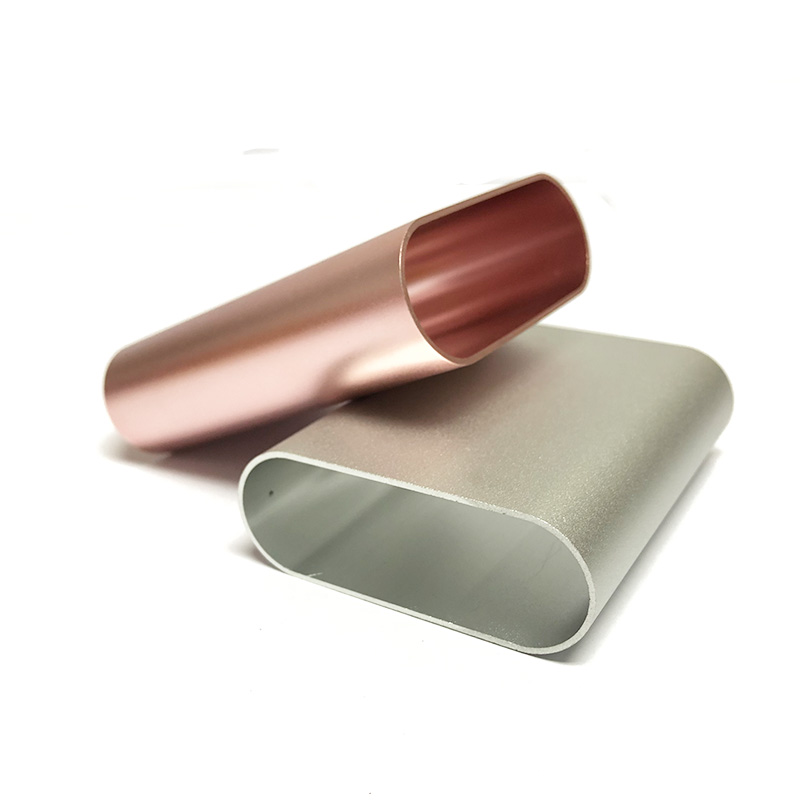

With the rapid development of electronic products, as the protective packaging of electronic products, the types of materials are also very wide, and the most popular one is aluminum profile shell. It is based on the conventional titanium plating process to increase the pre plating and electroplating process steps. The aluminum profile process is to place the activated plated parts in the aqueous solution of salt and hydrochloric acid for chemical treatment; it can be processed into various forms of gold , color, black and other bright series of aluminum products. Aluminum alloy shell in the process of drawing precautions, the following by zhiyahui for you to introduce.

1. The drawing must be carried out on the drawing frame when the aluminum alloy profile is cooled to below 50 degrees. If the temperature is too high, the drawing will not only burn the human body and burn the wool, but also show twists and turns before and after aging due to the failure to completely eliminate the internal stress of the aluminum alloy profile, poor function and other waste products.

2. The control of the stretching amount is at 1%, and it should be noted that too high stretching amount will lead to the scale error of head, middle and tail, the appearance of water like twist (scale) mark, low elongation, high hardness and brittle (low plasticity). If the tensile strength and hardness of the profile are too low, even the aging (quenching) can not improve the hardness. The profile is easy to arc and zigzag (commonly known as big knife bending).

3. In order to control the tensile deformation and the scale change of the whole profile, it is necessary to select suitable special clamping pad and appropriate method. In particular, the opening material, arc material, cantilever material, and zigzag shape profile should pay more attention to the reasonable and useful use of the stretching clamp pad.

4. Pay attention to the stress conditions of small feet, thin teeth, long legs, arc surfaces, inclined surfaces, openings, viewpoints, etc. of profiles with high width thickness ratio, long suspended wall, large radian, great wall thickness and strange shape, so as to avoid the defects such as partial or point size deformation, twist, screw, etc. of profiles.

5. Because the wool has the effect of heat resistance, the aluminum profile with high demand for decorative appearance must be turned up and down to facilitate the uniform heat dissipation and reduce the horizontal bright spots caused by the uneven crystallinity of heat dissipation, especially for the large wide surface and thick wall aluminum profile.

6. In the process of reclaiming, moving and stretching, it is not allowed to rub, pull, stack, jam and entangle with each other, and a certain interval shall be reserved between each other. The aluminum alloy profiles that are easy to be zigzagged and long or short of discharge shall be disposed in time, and the maintenance and disposal between each other shall be done if necessary.